Description

Product Description

Rovmaker Ip68 Plug Socket 4 Pin Connector With Male and Female Industrial Plug and Socket

- Small volume and lightweight, small footprint, professional wet plug.

- High seawater corrosion-resistant stainless steel shell material.

- Standard pin and hole position distribution, 7/16″-20 UNF tail thread, can be exchanged with different brands of the same model.

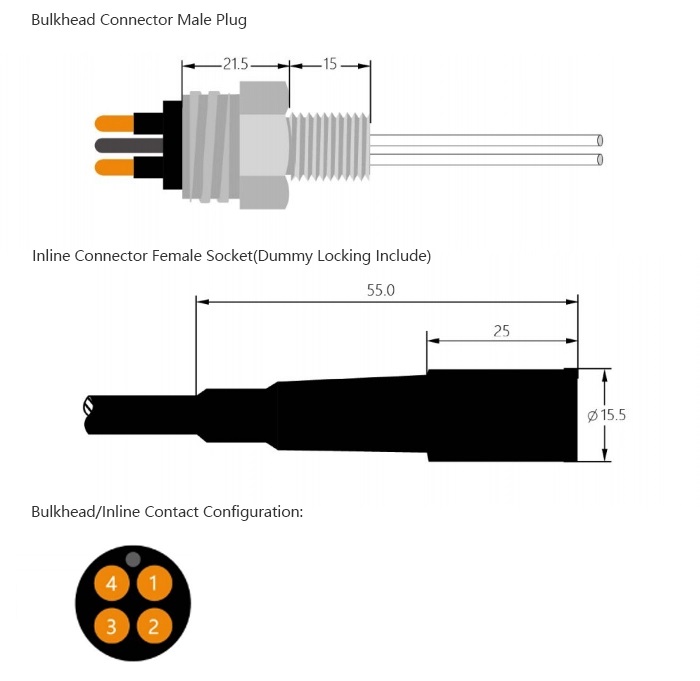

Dimensions Detail

Specification

|

STRUCTURE

|

MATERIALS AND SPECIFICATIONS

|

|

Main

|

The seawater corrodes stainless steel

|

|

Install screw

|

7/16-20 UNF thread length is 15/19mm

|

|

Socket head

|

Neoprene (special mixing rubber for underwater connector)

|

|

Contact Pin

|

Gold-plated copper alloy, American standard pin

|

|

Positioning pin

|

303 stainless steel (2 needle Ø 3.2, 3/4 needle Ø 2, 5/6/8 needle don’t need)

|

|

O-rings

|

Nitrile rubber, the imported o-rings, parker 2-014, Ø 12.42 x 1.78

|

|

Locking lid

|

Polyformaldehyde resin (POM)

|

|

Cable plug body

|

Special polyether

|

|

Install line

|

Teflflon, silver-plated pure copper.

|

|

End cap

|

Neoprene (special mixing rubber for underwater connector)

|

|

Cable plug

|

Pressure-resistant seawater special cable.

|

TECHNICAL PERFORMANCE

|

ITEM

|

RATING VALUE

|

|

Depth

|

0~1000 meters

|

|

Voltage

|

300V (resistance to voltage is greater than 1500V 60s)

|

|

Working current

|

2A~16A

|

|

Insulation resistance

|

> 1000 m Ω (room temperature)

|

|

Wet insertion frequency

|

> 500 times

|

|

Working temperature

|

(-4~60)°C

|

Pre-cautions

*Always apply grease before mating.

* Disconnect by pulling straight, not at an angle.

* Disconnect by pulling straight, not at an angle.

* Do not pull on the cable and avoid sharp bends at cable entry.

* When using a bulkhead connector, ensure that there are no angular loads.

* All kinds of connectors should not be exposed to extended periods of heat or direct sunlight.

* When using a bulkhead connector, ensure that there are no angular loads.

* All kinds of connectors should not be exposed to extended periods of heat or direct sunlight.

Greasing and mating above water (dry mate) :

* Connectors must be greased with Molykote 44 Medium(recommended brand) before every mating.

* A layer of grease corresponding to a minimum 1/10 of socket depth should be applied to the female connector.

* The inner edge of all sockets should be completely covered, and a thin transparent layer of grease left visible on the face of the connector.

* After greasing, fully mate the male and female connector in order to secure optimal distribution of grease on pins and in sockets.

* To confirm that grease has been sufficiently applied, de-mate, and check for grease on every male pin. Then re-mate the connector.

Greasing and mating underwater (wet mate) :

* Connectors must be greased with Molykote 44 Medium(recommended brand) before every mating.

* A layer of grease corresponding to approximately 1/3 of socket depth should be applied to the female connector.

* All sockets should be completely sealed, and a transparent layer of grease left visible on the face of the connector.

* After greasing, fully mate the male and female connector and remove any excess grease from the connector joint.

Cleaning

* General cleaning and removal of any accumulated sand or mud on a connector should be performed using spray based contact cleaner (isopropyl alcohol).

* New grease must be applied again prior to mating.

Use of Loctite

* For locking metallic connectors, the use of Loctite 243 is recommended.

Installation Requirements

- End surface roughness requirements Ra1.6 in the diameter of the screw hole around 25mm when threaded hole installation.

- Hole diameter should be between Ø 11.2 ~ Ø11.4 mm and roughness requires Ra1.6 in the diameter of the screw hole around 25mm when through-hole installation.

- Before installing, make sure to apply a thin layer of silicone oil to the o-ring, not too thick.

More Pins

Reviews

There are no reviews yet.